Hydrogen (H2) and helium (He) prospecting involves identifying and evaluating potential sources of these valuable gases. Accurate detection and measurement are essential for assessing their viability as energy sources. EnerSol’s advanced diagnostics provide non-intrusive, real-time monitoring to detect and quantify H2 and He concentrations, helping operators assess reservoir potential and ensure efficient exploration.

Flare gas emissions contribute to pollution and climate change, making monitoring crucial for public health and air quality. EnerSol’s N2 dilution rate measurement technique accurately quantifies flare gas rates on HP and LP flare lines. On-site compositional analysis and calorific value measurements enable precise emissions calculations, helping operators easily track and control flare emissions.

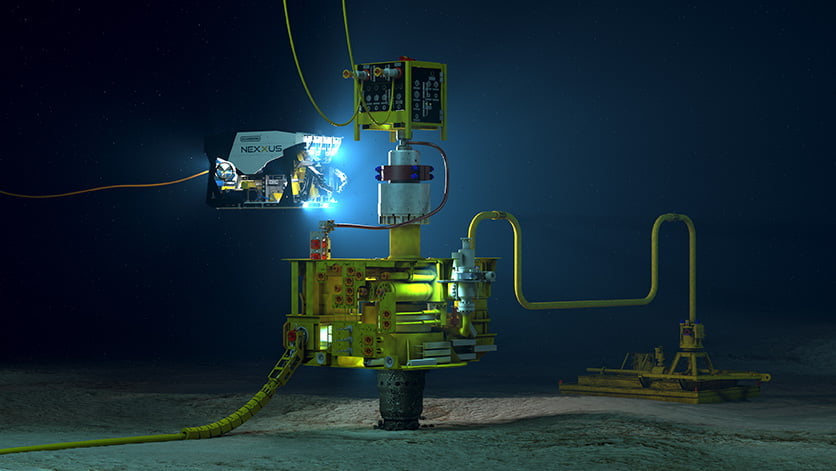

Effluent discharge monitoring is crucial for ensuring environmental safety by detecting contaminants like oil-in-water (OIW) and chemicals such as triazine. EnerSol’s interventionless technology enables real-time monitoring of effluent discharge, ensuring compliance with environmental standards. It helps detect potential contaminants and assess discharge quality.

Surveillance wells are key to monitoring carbon capture and storage (CCUS), detecting leaks and pressure changes to ensure safety and integrity. EnerSol’s interventionless technology can verify downhole gauges or measure bottom-hole pressure, while also providing real-time compositional monitoring and assessing CO2 breakthrough through mini-production tests.

EnerSol’s acoustic EzScan system is widely used during P&A activities to monitor fluid levels non-intrusively. Accurate fluid level monitoring ensures proper cement placement, achieving zonal isolation and preventing fluid migration or environmental risks

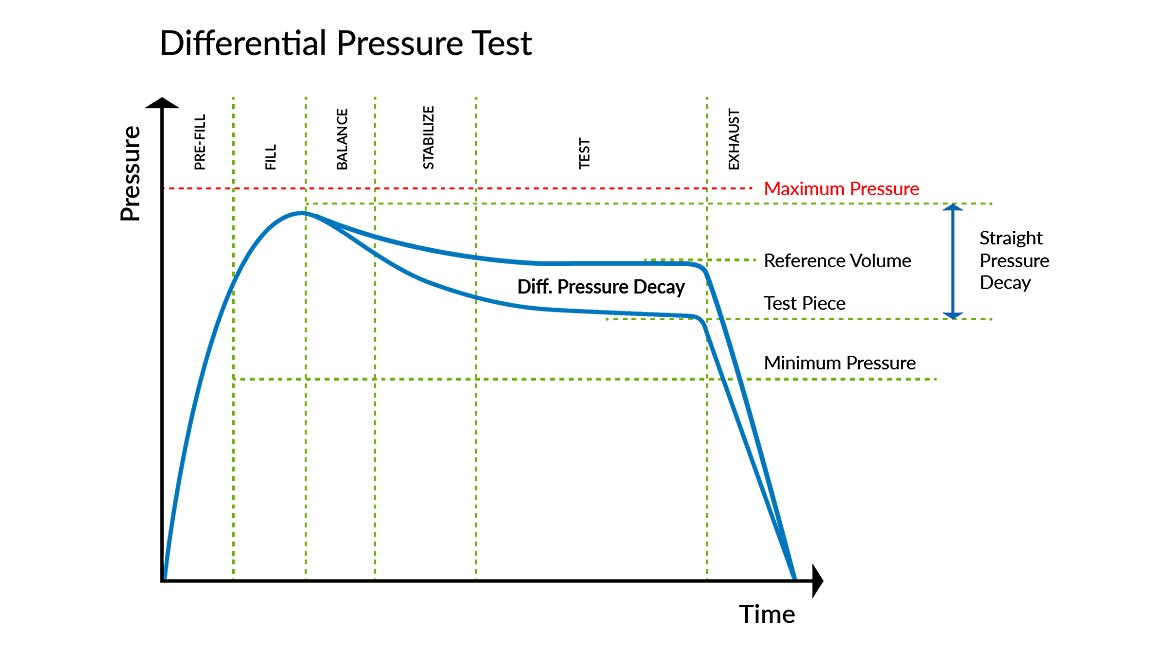

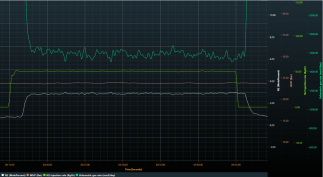

The Extended Leak-Off Test (XLOT) measures stress in wells to predict stability. It involves multiple cycles and longer data collection to determine fracture propagation pressure (FPP). EnerSol uses ATEX-rated equipment for rigless XLOT testing, aiding in stability, fracturing, and sand production evaluations.

EnerSol ensures P&A success with in-situ integrity checks using pressure monitoring and leak detection. For P&A’d wells, our system enables efficient ongoing monitoring, ensuring safety, compliance, and long-term stability.

EnerSol’s EzScan System and Acoustic Software empower operators to locate the Top of Cement (TOC) and cement plug depths without intervention. This reduces uncertainty, minimizes rig time, and cuts costs, ensuring efficient and successful P&A operations.

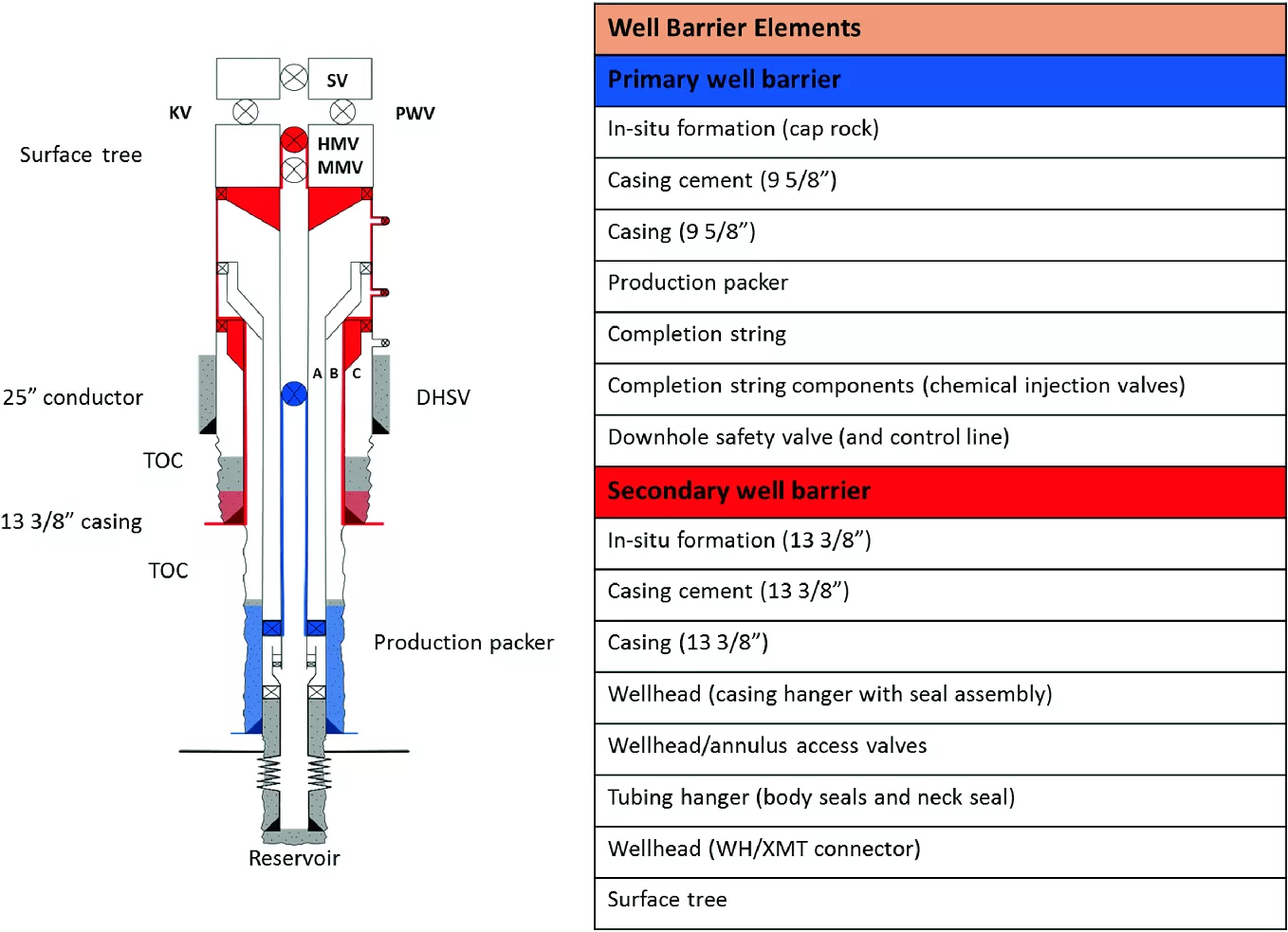

Well barrier schematics verification is crucial for ensuring well safety and compliance. EnerSol offers advanced solutions to help verify well barrier schematics, helping operators confirm barrier integrity and maintain operational safety without intrusive interventions.

Well health certification and risk trending are essential for managing well integrity over time. EnerSol offers innovative solutions to monitor well conditions, track risk trends, and provide comprehensive assessments, enabling operators to make informed decisions and maintain long-term well safety.

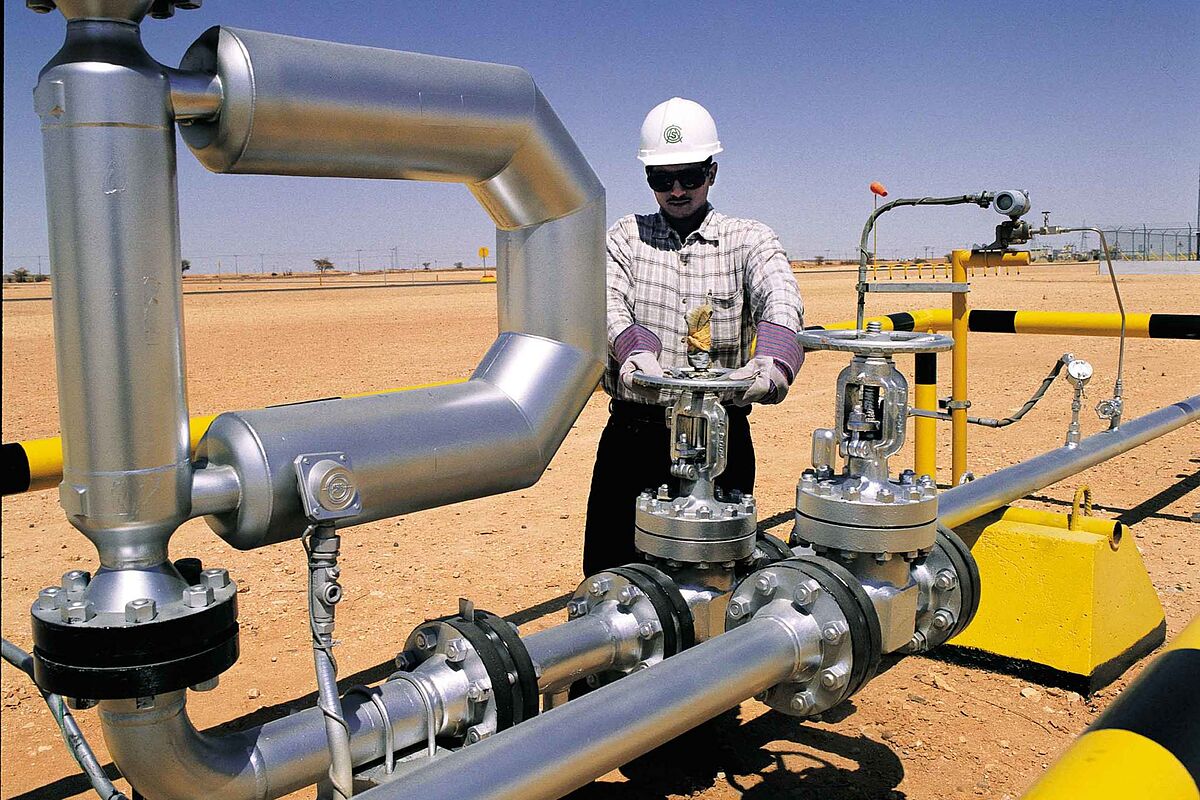

Wellhead and Christmas tree inspections and maintenance are critical for ensuring safe and reliable operations. EnerSol provides advanced, interventionless solutions to assess the condition of wellheads and Xmas trees, helping operators optimize maintenance schedules and prevent potential failures.

Top-up and bleed-off exercises are crucial for maintaining well pressure and fluid balance. EnerSol offers innovative techniques to evaluate restricted volumes, optimizing top-up and bleed-off routines for improved efficiency and reduced operational risks.

Tubing integrity checks are essential for ensuring safe and efficient well operations. EnerSol offers advanced, interventionless solutions to assess tubing conditions, enabling operators to detect potential issues and take proactive measures without disrupting production.

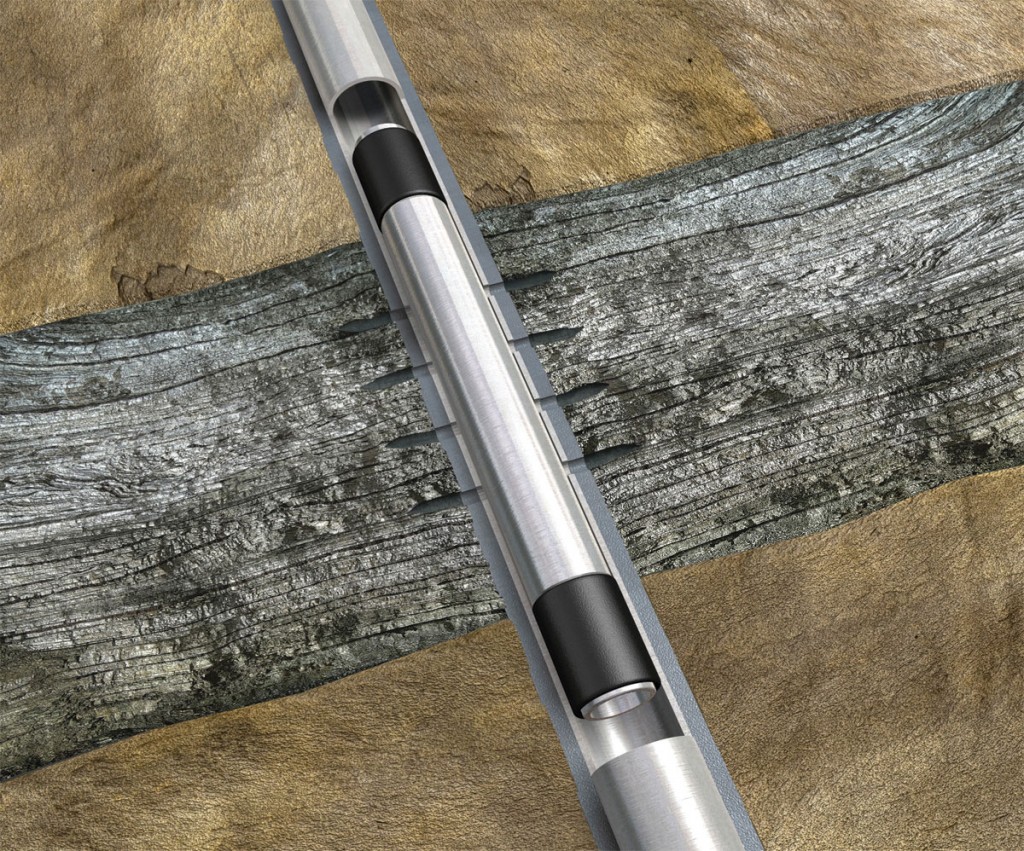

Patch and seal verification is vital for confirming the effectiveness of integrity repairs. EnerSol provides advanced methods for non-intrusive verification, ensuring the reliability of patches and seals without the need for invasive procedures.

Leak rate information is essential for assessing risks related to sustained casing pressure scenarios. EnerSol offers proprietary methods for accurate leak rate quantification, eliminating the need for conservative pressure build analysis.

Leak point identification is crucial for evaluating the risks associated with leaks and determining the appropriate mitigation strategies. EnerSol’s interventionless, multi-method approach provides accurate leak point information, enabling operators to assess risks and choose effective solutions without intrusive interventions.

Hanger leaks are a common integrity concern in aging wells. EnerSol provides interventionless diagnostic techniques to accurately assess the size and location of leaks at or near the casing hanger, enabling timely detection and mitigation

EnerSol provides advanced solutions for conducting integrity checks on conductors and risers, enabling operators to monitor structural health and identify potential risks

EnerSol offers non-invasive solutions to monitor the integrity of downhole chemical injection lines, allowing operators to detect potential integrity issues early without the need for well intervention.

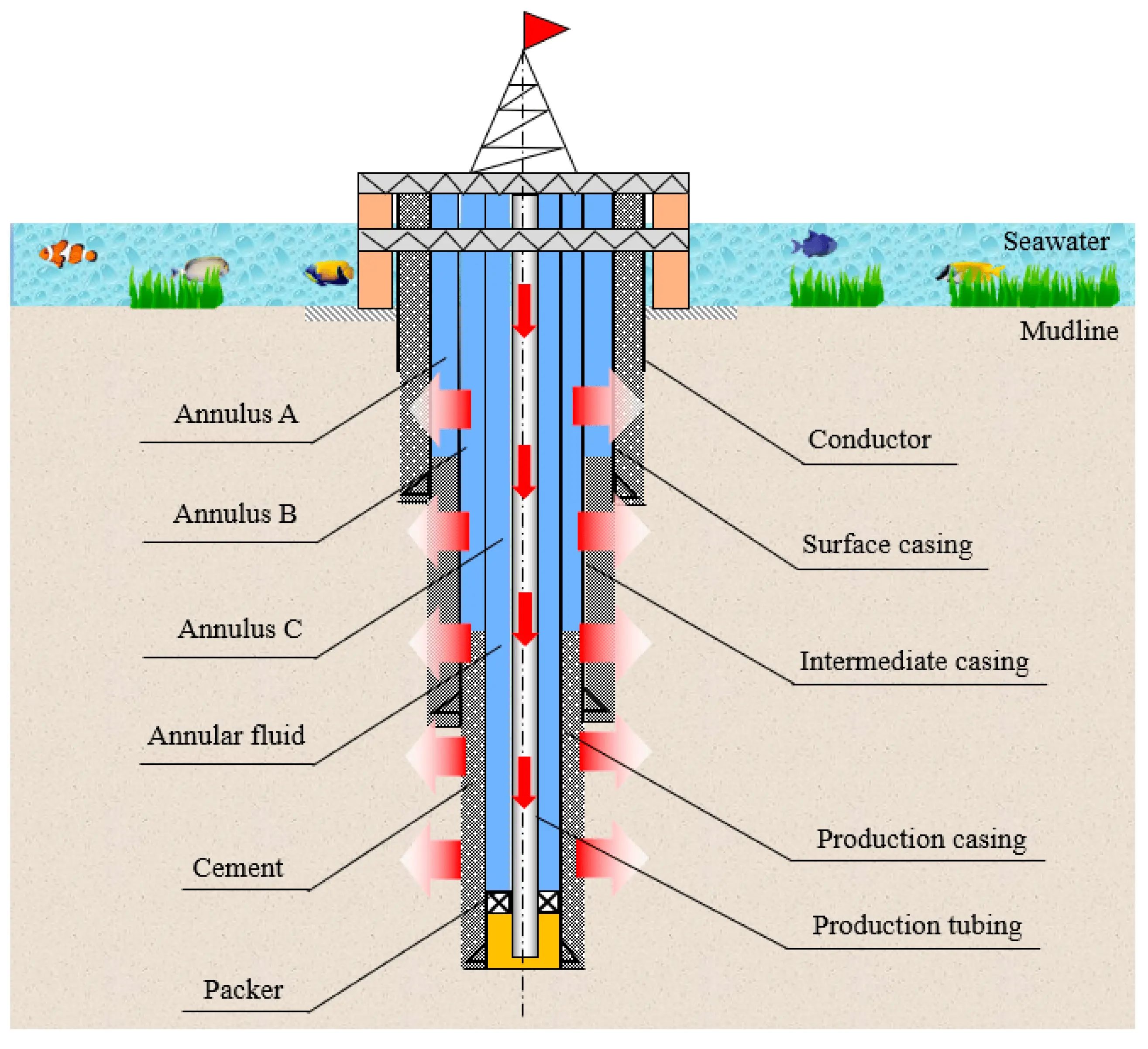

EnerSol offers proprietory solutions to perform annulus integrity checks without the need for well intervention, enabling operators to assess well conditions and implement proactive surveillance and risk mitigation strategies efficiently.

Annular forensics helps identify the source of well integrity problems, such as leaks, by analyzing the fluids contained in the annular space. EnerSol provides advanced solutions to sample and diagnose these conditions, allowing operators to take targeted actions and effectively maintain well integrity.

Well slugging can significantly impact production efficiency and system stability. EnerSol provides advanced monitoring and diagnostic services to identify the causes and reduce the behavior of slugging in wells.

Effective solids and asphaltene management is critical for maintaining production efficiency and equipment integrity. EnerSol offers sampling and characterization services to identify the composition and behavior of solids and asphaltenes in production streams.

Our real-time diagnostics help identify inefficiencies like emulsions, carryovers, or excessive retention times, allowing operators to fine-tune processes for maximum efficiency. With EnerSol’s services, operators can improve production output, reduce chemical usage, and enhance the overall performance of their separation systems.

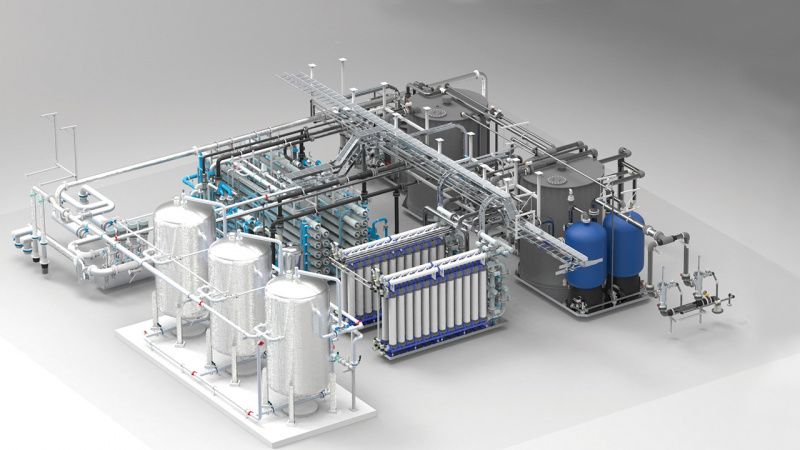

Monitoring the performance of process modules is critical for ensuring operational efficiency and reliability in oil and gas facilities. EnerSol offers surveillance solutions to track key parameters such as flow rates, pressures, temperatures, and separation efficiencies across process modules.

EnerSol’ diagnostic techniques help operators evaluate chemical effectiveness and fine-tune dosages. By leveraging EnerSol’s services, operators can reduce chemical costs, enhance production efficiency, and maintain asset integrity.

EnerSol’s real-time tracer dilution system offers a precise, efficient alternative to traditional production testing, reducing costs, operational footprint, and crew needs while delivering accurate flow rates and gas compositional analysis.

By providing real-time data on flow rates, pressure, and pump performance, our solutions enable operators to identify inefficiencies, mitigate risks such as sanding or fluid slugging, and fine-tune operations for maximum output.

EnerSol is advancing proprietary methods to accurately quantify and monitor water cut in real-time using innovative side-stream equipment, providing continuous and reliable data for enhanced production management.

This cost-effective, accurate solution eliminates the need for traditional separators or inline meters, reduces operational costs, and minimizes environmental impact by avoiding methane emissions and flaring.

Our services help operators track fluid movements, pressure changes, and flow rates during stimulation, ensuring efficient operations and optimal resource utilization. With EnerSol’s monitoring capabilities, operators can enhance the effectiveness of stimulation treatments, minimize risks, and achieve improved well performance.

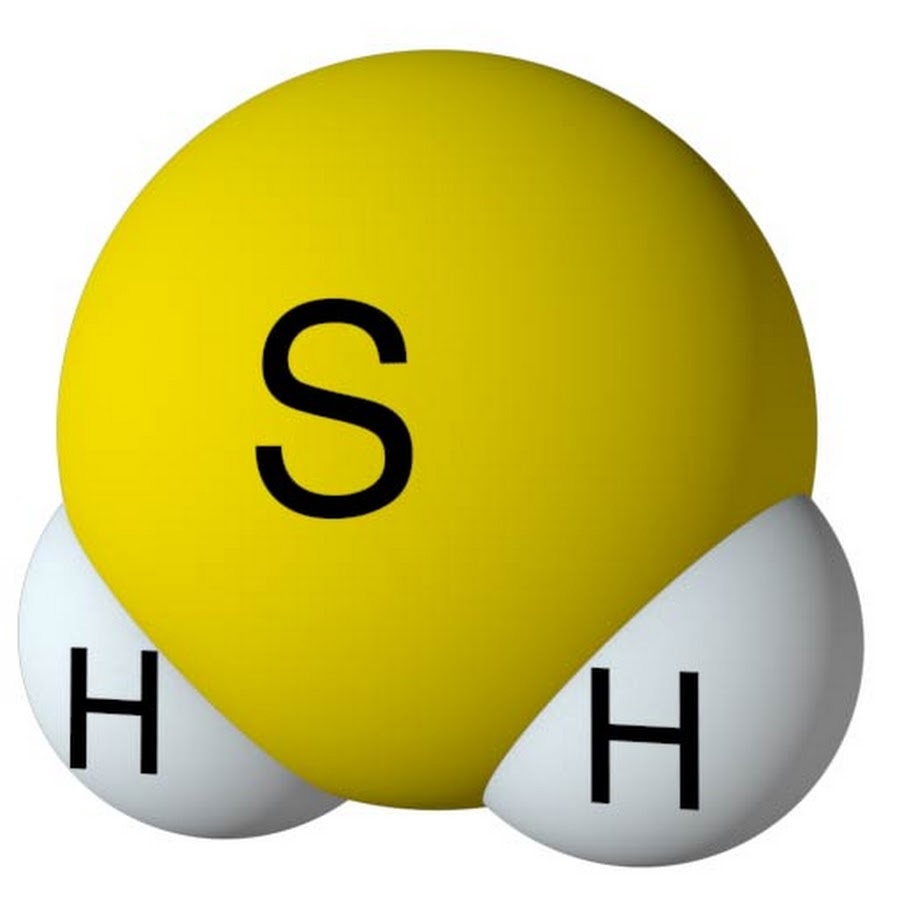

H₂S Scavenger Trials & Optimizations are crucial for efficiently managing hydrogen sulfide levels in production systems. EnerSol offers specialized services to evaluate and enhance H₂S scavenger performance, ensuring optimal chemical dosing and cost-efficiency.

H₂S Process Mapping is essential for understanding and managing hydrogen sulfide distribution within production and processing systems. EnerSol provides advanced solutions for real-time H₂S measurement and visualization, allowing operators to identify high-risk areas, optimize process flows, and mitigate corrosion and safety hazards.

H₂S Monitoring of Assets during Flushing is critical for ensuring safety and operational efficiency in oil and gas operations. EnerSol provides advanced, real-time monitoring solutions to detect and measure hydrogen sulfide levels during flushing processes, ensuring the integrity of equipment and the safety of personnel.

EnerSol N2 dilution method allow operators to validate meter performance in real-time, identify calibration needs, and correct discrepancies. This reduces the risk of errors in flow measurements, improves data quality, and minimizes downtime associated with traditional verification methods.

Gas Lift Injection Rate Verification is crucial for maintaining optimal well performance and maximizing production efficiency. EnerSol provides proprietary solutions to accurately monitor and verify injection rates in real-time, ensuring the gas lift system operates at peak efficiency.

Gas Lift Design Verification and Optimization are vital for enhancing production efficiency in oil and gas operations. At EnerSol, we offer proprietary solutions that deliver accurate data and actionable insights to ensure gas lift systems operate effectively.

Full Field Nodal Analysis and Gas Network Optimization are critical for maximizing production efficiency and ensuring sustainable field operations. At EnerSol, we offer advanced diagnostic and monitoring solutions to support these efforts, enabling operators to optimize flow performance across the entire production system.

Emulsion and turbidity issues can significantly impact oil and gas production by reducing efficiency, increasing operational costs, and complicating downstream processing. At EnerSol, we provide advanced monitoring solutions to help operators diagnose and resolve these challenges effectively.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse pretium eros et condimentum semper. Maecenas lobortis nunc vel sodales rutrum.

EnerSol is developing real-time GOR and CGR monitoring through advanced tracer dilution techniques. This cost-effective, accurate solution eliminates the need for traditional separators, cuts operational costs, and minimizes environmental impact by preventing methane emissions and flaring.

EnerSol’s real-time tracer dilution system offers a highly accurate, efficient alternative to traditional production testing methods, reducing operational footprint, costs, and crew requirements while providing precise flow rates.

EnerSol provides interventionless surveillance during well stimulation, offering real-time data to optimize operations, reduce risks, and enhance success rates.

Using EnerSol’s innovative Acoustic Gradient Survey Technology, combined with portable Tracer based flow metering systems, intereferance tests can be conducted with highly portable equipment, zero intervention and no production deferement.

EnerSol offers interventionless diagnostics, providing real-time, high-quality data to streamline well evaluation and restoration. Its solutions enable operators to identify issues, enhance monitoring, and implement efficient reactivation strategies.

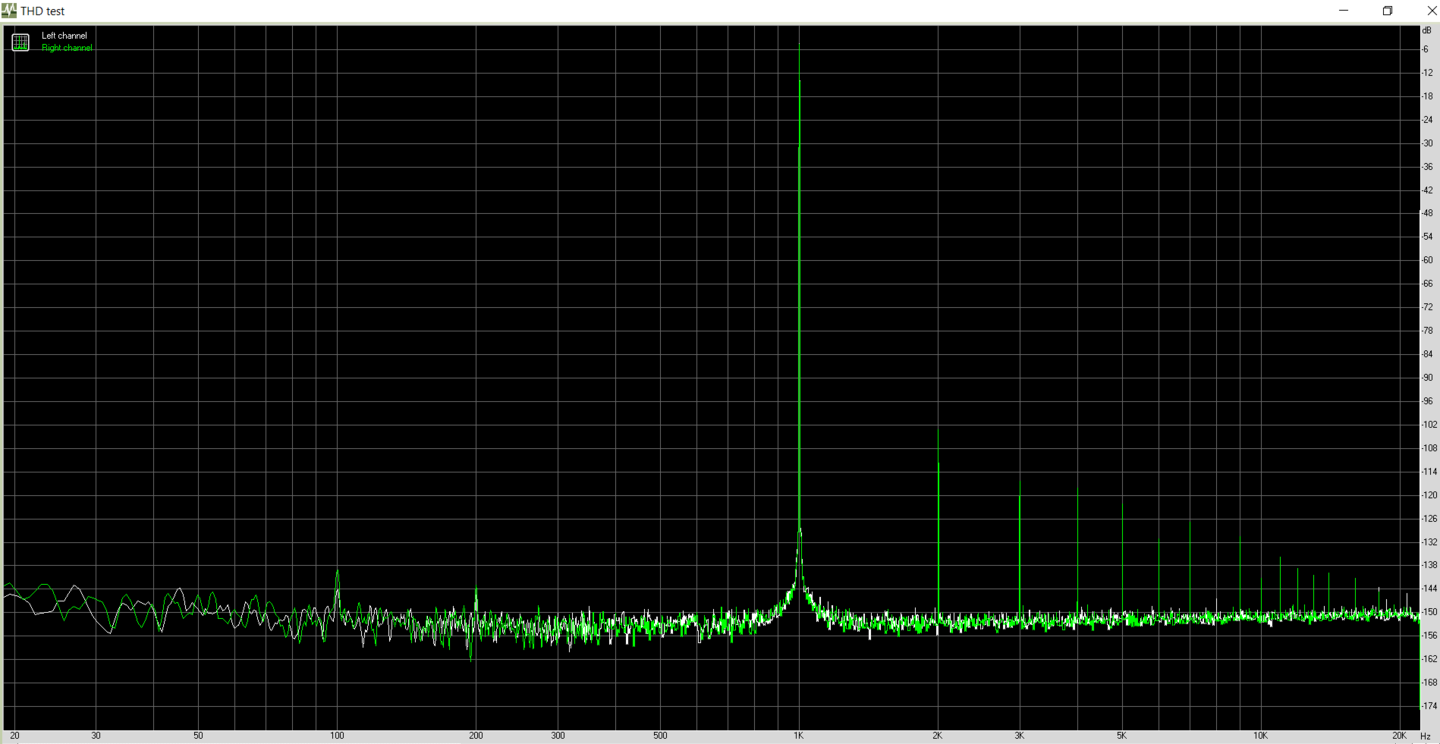

EnerSol’s ATEX Zone 2 analyzers use TDLAS and Raman Spectroscopy for real-time hydrocarbon and contaminant trending, reducing logistics, footprint, and personnel needs while enhancing data accuracy.

Utilizing EnerSol’s non intervention based acoustic measurement techniques increases chances of successful sample capture by providing key information associated with real time monitoring

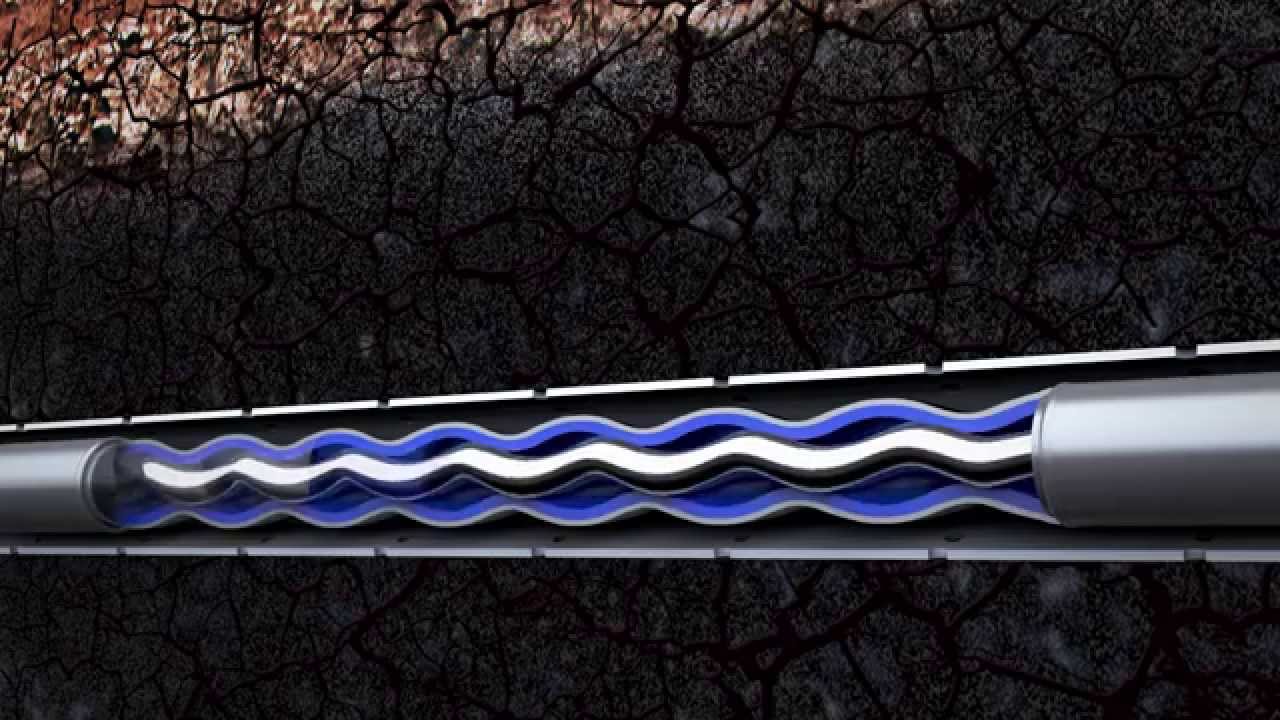

Acoustic SGS offers a cost-effective, non-intrusive method to measure downhole pressure gradients, gas-liquid interfaces, and anomalies with minimal production losses.

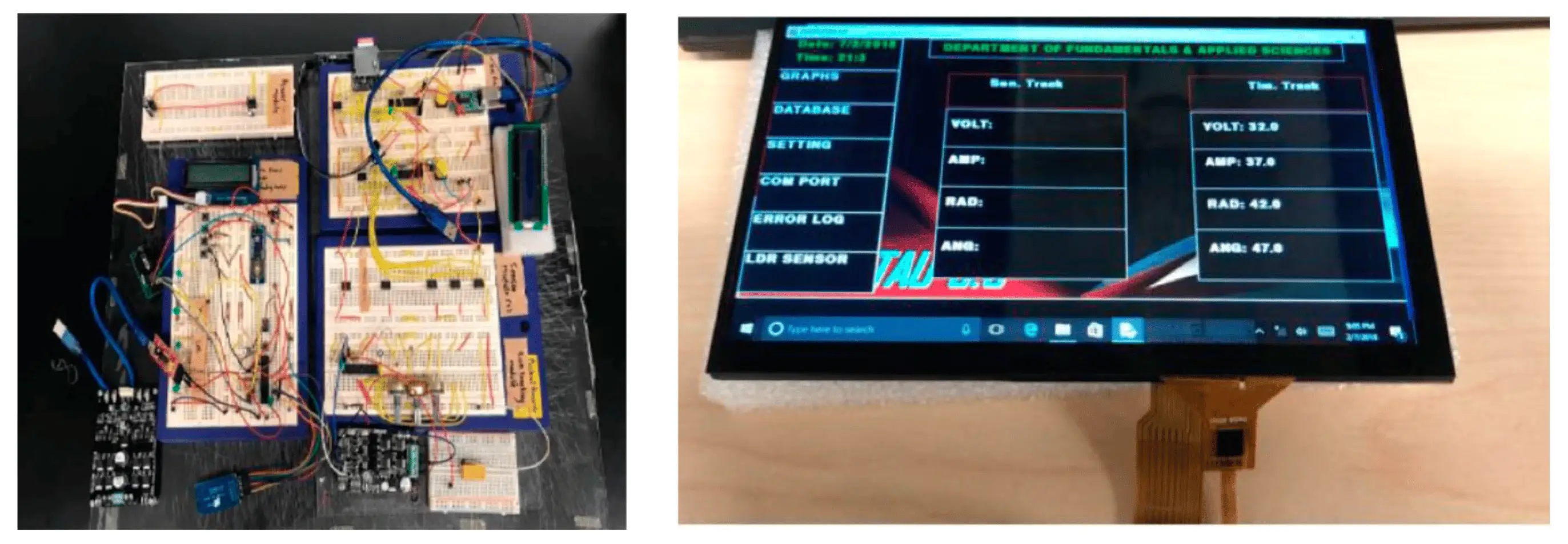

Scan-Well’s EzScan and Acoustic Metering Systems Enhance Safety and Efficiency by gathering valuable downhole data without intervention.

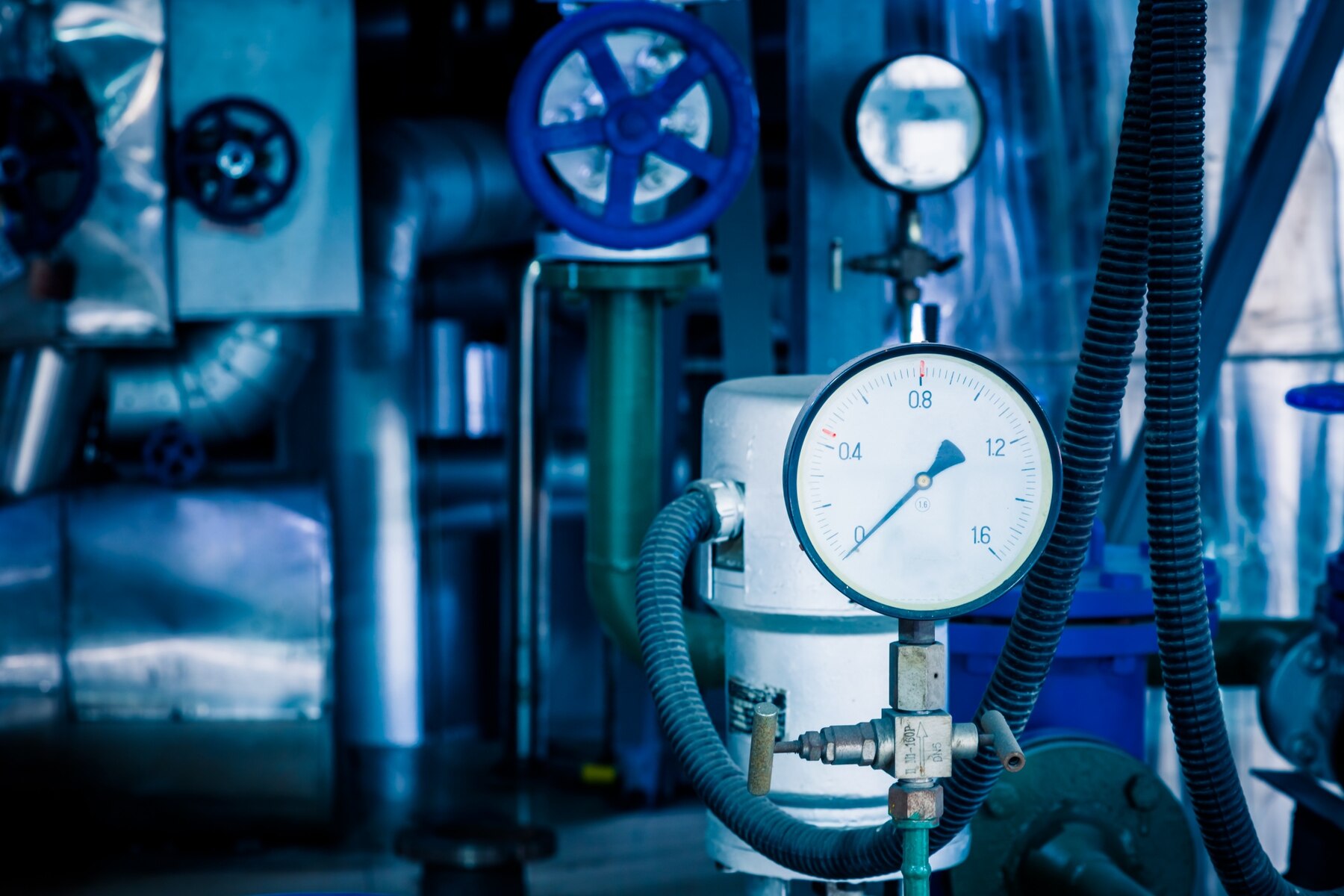

Wireless pressure monitoring systems on oil rigs provide real-time data on downhole and surface pressures without the need for physical cables or interventions. These systems enhance operational efficiency, improve safety, and reduce costs by enabling continuous monitoring, faster decision-making, and maintenance optimization.

EnerSol’s SSSV verification ensures the functionality of surface-controlled subsurface safety valves (SC-SSSV), crucial for halting flow during emergencies. Using our Acoustic Metering System (AMS), we conduct acoustic pulse surveys to assess the SC-SSSV’s condition, accurately identifying the flapper valve’s position (open or closed) by monitoring control panel data.

A “packer leak” occurs when a packer fails, causing fluid migration and high tubing annulus pressure. EnerSol’s Leak Metering Survey (LMS) detects these leaks by analyzing data such as compositional analysis, liquid levels, leak rates, and pressure changes, ensuring accurate leak detection and well integrity.

EnerSol’s GLV verification services quantify leak rates and tubing-to-annulus communication in a cost-effective manner, reducing downtime. Using advanced Coriolis meters, gas analyzers, and acoustic systems, we provide accurate assessments to optimize gas lift performance.

Monitoring ESP wells ensures optimal performance and prevents failures. EnerSol offers cost-effective, interventionless solutions for tracking key parameters like flow rates, downhole liquid levels, and bottomhole pressures, maximizing efficiency and asset value.

EnerSol provides interventionless DHSV verification to ensure well integrity and compliance. Using EzScan acoustic tools and Leak Metering System, we assess valve functionality, pressure build-up, and leak rates with minimal disruption, enhancing safety and optimizing production.

EnerSol provides cost-effective, interventionless solutions for accurate bottomhole pressure validation. Using acoustic surveillance, our method eliminates wireline intervention, minimizes production losses, and delivers rapid, reliable wellbore data.

The Extended Leak-Off Test (XLOT) measures stress in wells to predict stability. It involves multiple cycles and longer data collection to determine fracture propagation pressure (FPP). EnerSol uses ATEX-rated equipment for rigless XLOT testing, aiding in stability, fracturing, and sand production evaluations.

EnerSol’s ATEX-Rated Online Water Property System Enables Real-Time Monitoring and Logging of Water Properties During Clean-Up and DST Activities, Allowing Operators to Accurately Assess Clean-Up Criteria and Characterize Formation Water Across Different Zones.

Real-Time Fluid Level and BHP Monitoring: Scan-Well’s EzScan Acoustic System Enhances Safety and Efficiency in Managed Pressure Drilling with Nitrogen Gas Cap Solutions.

EnerSol’s ATEX Zone 2-rated gas analyzers use TDLAS for real-time contaminant and hydrocarbon analysis, providing high-frequency data (up to 1Hz) and improving safety, efficiency, and operational simplicity over traditional methods.

Enhancing Hydrocarbon Analysis: Scan-Well’s ATEX Zone 2 Gas Analyzers Leverage IR, TDLAS & Raman Spectroscopy for Accurate, Onsite Measurements Without Legacy Gas Support Challenges.

EnerSol provides interventionless diagnostic technology, improving surveillance capabilities, and efficiently providing valuable data.

EnerSol delivers interventionless surveillance technology to support P&A and decommissioning activities, enhancing monitoring capabilities during operations while offering cost-effective solutions, efficient processes, and valuable insights.

EnerSol offers proprietary interventionless surveillance technology to enhance asset and well integrity, delivering value through cost-effective monitoring, efficient operations, and valuable insights.

EnerSol provides interventionless surveillance solutions to enhance process and production optimization, driving asset value through cost-effective monitoring, efficient operations, and valuable insights.

EnerSol delivers interventionless surveillance solutions to optimize reservoir management, enhancing asset value through cost-effective monitoring, efficient operations, and reliable evaluations.

EnerSol provides advanced technology adding value for completion and workover operations, offering real-time monitoring and data collection without the need for intervention. Our solutions optimize well performance, ensure safety, and reduce operational downtime, enhancing the value of your assets.

EnerSol offers technology for interventionless surveillance, enabling real-time monitoring and data acquisition. Our solutions improve operational efficiency, enhance safety, and reduce costs across drilling, exploration, and appraisal activities.